News Center

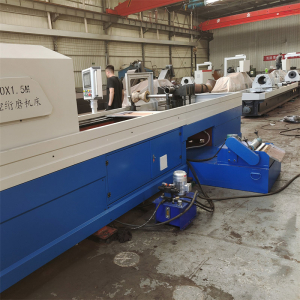

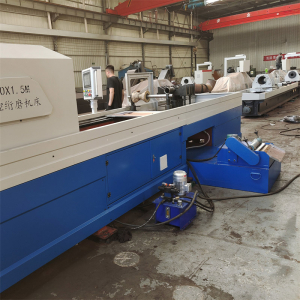

The Deep Hole Scraping and Rolling Machine is an efficient and precise deep hole processing equipment, which plays an important role in many industries.In the field of aerospace, deep hole scraping and rolling machine is used to process high-precision deep hole parts such as aircraft engines and…

2024/10/30 15:03

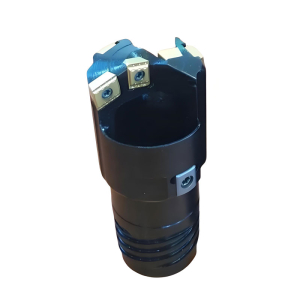

In the field of mechanical processing, the Precision Boring Head is a key component of precision processing equipment, and its performance and precision are directly related to the quality and efficiency of the processed products. In order to ensure that the boring head can operate stably for a…

2024/10/26 09:14

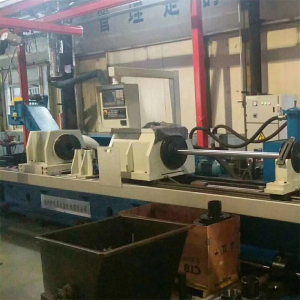

The main technical parameters of Deep Hole Honing Machine include the following aspects:Processing size parameters:Hole Honing diameter range: refers to the Deep Hole Honing Machine can process the diameter of the hole size range, for example, some equipment hole honing diameter range is φ25-φ250mm…

2024/10/10 14:19

Maintaining a CNC Deep Hole Drilling Machine is critical to ensuring its performance, extending its service life and improving machining accuracy. Here are some suggestions for maintenance:1. Clean regularlyClean workbenches and perimeters: Clean the work area regularly to remove chips and debris…

2024/09/25 14:10

Deep Hole Drilling and Boring Machine is a professional mechanical equipment for machining deep holes and complex cavities, mainly used in aerospace, automotive manufacturing, mold manufacturing and heavy machinery and other fields. Its main uses include the following aspects:First, Deep Hole…

2024/09/11 15:07

Cylinder Honing Head plays a vital role in engine manufacturing and maintenance. Its main role is to precision machining the inner surface of the engine cylinder to improve its geometric accuracy and surface quality. Through the Honing process, the Cylinder Honing Head can remove the small…

2024/09/05 09:14

CNC Deep Hole Drilling Machine is a high-precision machine tool specially designed for deep hole machining. It is mainly used to manufacture deep holes with a length-diameter ratio greater than 20:1, and is widely used in automobile manufacturing, aerospace, mold manufacturing, energy equipment and…

2024/08/28 14:37

The Deep Hole Drill Head, a key tool in modern machining, has a unique design optimized for precise drilling deep inside materials. These drills are used in a wide range of industries, including automotive manufacturing, aerospace, energy extraction, heavy machinery, and precision instrumentation.…

2024/08/21 15:04

Deep Hole CNC Scraping and Rolling Machine maintenance precautions include:Regular cleaning: Keep the inside and outside of the machine clean, clean the chip and dirt regularly.Check the lubrication system: make sure that the lubricating oil or grease is sufficient, and check that the lubrication…

2024/08/14 10:22

Maintenance of Hydraulic cylinder CNC machine includes:Regularly check the oil level: keep the hydraulic oil in the specified range to avoid oil shortage or oil quality deterioration.Clean the cylinder: Clean the cylinder and oil seal regularly to prevent dirt from entering the hydraulic system.…

2024/08/10 15:14

Deep hole scraping and rolling machine maintenance is very important, the main points are as follows:Daily cleaning: Remove chips, oil and dust from the surface of the machine, especially residue from the processing area, to ensure that the equipment is kept clean during efficient operation.…

2024/07/30 15:00

CNC Deep Hole Honing Machine is a precision machining equipment, and its maintenance is crucial to ensure long-term stable operation of the equipment and maintain machining accuracy. The following is about the maintenance of CNC Deep Hole Honing Machine precautions:1. Daily cleaning: clean the…

2024/07/22 13:56