Milling Machine Tools

Milling Machine Tools Milling machine The workpiece by rotating milling cutter to achieve material removal and shape shaping. During the machining process, the workpiece is fixed on the workbench of the machine tool, and the milling cutter is rotated at high speed by the spindle drive. At the same time, the feed mechanism of the machine tool controls the relative motion between the workpiece and the milling cutter, so that the milling cutter can cut the workpiece according to the predetermined trajectory.

Product description

As an indispensable and important equipment in modern industrial manufacturing, Milling Machine Tools provides strong support for the manufacturing of various parts and products with its efficient and accurate processing capabilities.

Milling Machine Tools are widely used in aviation, automotive, mold, machinery and other fields. In the aviation field, milling machines are used to process aircraft parts, such as wings, fuselages, etc., to ensure the accuracy and safety of aircraft structures. In the automotive sector, milling machines are used to manufacture key components such as engines and chassis to improve vehicle performance and reliability. In the mold manufacturing industry, milling machines are used to process molds of various complex shapes to meet the production needs of high precision and high efficiency.

The development trend of Milling Machine Tools

With the continuous progress of industrial technology, Milling Machine Tools are also constantly developing and innovating. In the future, milling machines will develop in the following directions:

1. High efficiency: By optimizing the machine structure, improving the cutting speed and accuracy, to achieve more efficient processing capacity and reduce production costs.

2. Intelligent: With the help of Internet of Things, big data and other technologies, remote monitoring, fault diagnosis and predictive maintenance of machine tools can be achieved to improve the utilization rate and reliability of equipment.

3. Flexibility: The use of modular design, so that the machine can adapt to different processing needs, improve the flexibility and adaptability of the production line.

4. Green environmental protection: pay attention to the energy saving and emission reduction and environmental protection performance of the machine tool, the use of environmentally friendly materials and processes to reduce energy consumption and pollution in the production process.

In short, Milling Machine Tools, as an efficient tool in modern industrial manufacturing, will continue to play an important role. With the continuous progress and innovation of technology, milling machines will achieve more efficient, intelligent, flexible and environmentally friendly processing capabilities in the future, injecting new vitality into the development of industrial manufacturing.

Product Pictures

About Company

Dezhou XinHongJi CNC Machinery Co., Ltd. Mainly engaged in Skiving Roller Burnishing,Hole Boring Machine,Honing Machine manufacturing.

We assure you that we will continue to serve our customers.

Engineering case

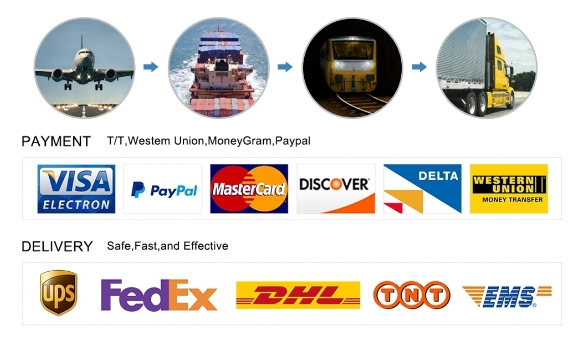

Payment and Transport

FAQ

Q: What are the core technologies of Milling Machine Tools?

A: The core technology includes high-precision spindle, high-speed cutting technology and intelligent control system to ensure processing accuracy and efficiency.

Q: How can enterprises maintain competitive advantage in the market?

A: Through continuous innovation, improve product quality and technical level, while strengthening marketing and after-sales service to meet customer needs.

Q: What are the future trends of Milling Machine Tools companies?

A: The future trend is intelligent, green and personalized development, enabling remote monitoring, fault diagnosis, reducing energy consumption, and providing customized solutions.