Cylinder Honing Head

Cylinder Honing Head is one of the key parts in the manufacturing process of automobile engine. Its function is to improve the air tightness and combustion efficiency of the cylinder by honing the cylinder wall to obtain a smooth inner surface.

The main structure of Cylinder Honing Head includes a honing head body with diamond sand and a conical handle for fixing the honing head body. In use, the honing head body is installed on the main shaft of the honing machine, and the cylinder wall is processed through the rotation and reciprocating movement of the honing head body.

The principle of Cylinder Honing Head is to friction the cylinder wall through the diamond sand on the honing head body to remove surface scratches and roughness, so as to achieve smooth processing of the cylinder wall. In the process of honing, the honing head body constantly enters and exits the cylinder wall, thus forming a cross mesh cutting track to improve the finish and accuracy of the cylinder wall.

In short, Cylinder Honing Head is a very important tool for automotive engine manufacturing, and its use can greatly improve the performance and life of the engine.

Product description

The working principle of a Cylinder Honing Head is similar to the use of sandpaper. It consists of a metal shell and a set of diamond grinding heads, which are mounted on the spindle of the honing machine and are rotated at high speed to cut the cylinder wall. The length of the honing head and the shape of the honing track can be adjusted according to specific needs.

When working, the honing head will reciprocate along the cylinder wall and rotate at the same time. The Cylinder Honing Head cuts the surface of the cylinder wall to remove the oxide and metal fatigue layer on the surface, while leaving a small wear mark to improve smoothness and reduce friction resistance. In addition, the honing head can also remove burrs and bumps on the cylinder wall, and form a uniform taper to improve the seal and combustion efficiency of the cylinder.

It should be noted that in the Honing process, the precision and grinding amount of Cylinder Honing Head have a crucial impact on the quality of the cylinder. Therefore, it is necessary to use a high-quality honing head and carry out strict control and monitoring during the processing.

The structure of Cylinder Honing Head is mainly composed of grinding part, honing oil hole, cooling system, etc. The following is the detailed structure of the Honing Head: 1. Grinding part: The grinding part of the Cylinder Honing Head is the core of the honing head, which is mainly composed of diamond abrasive particles and binder. The choice and arrangement of diamond abrasive particles will affect the efficiency and life of honing head. The grinding part of the honing head can be made into different shapes and specifications according to needs, such as cylindrical, spherical, cone and so on.

2. Honing oil hole: The oil hole of Cylinder Honing Head is used to inject honing fluid, so that the honing head can be cooled and lubricated during honing. The location and size of the oil hole will affect the flow and distribution of the honing fluid, which will affect the efficiency and life of the honing head.

3. Cooling system: The cooling system of Cylinder Honing Head is mainly composed of coolant channels and heat sinks. The coolant flows through the coolant channel of the honing head through the grinding part and the heat sink to take away the heat generated during the honing process and avoid overheating of the honing head.

4. Shank: The shank of the honing head is used to fix the honing head on the honing machine, and the shape and length of the shank will affect the stability and flexibility of the honing head. The handle is usually made of metal material.

It should be noted that the structure and design of Cylinder Honing Head have a crucial impact on honing effect and honing head life. Therefore, it is necessary to select and design according to specific needs.

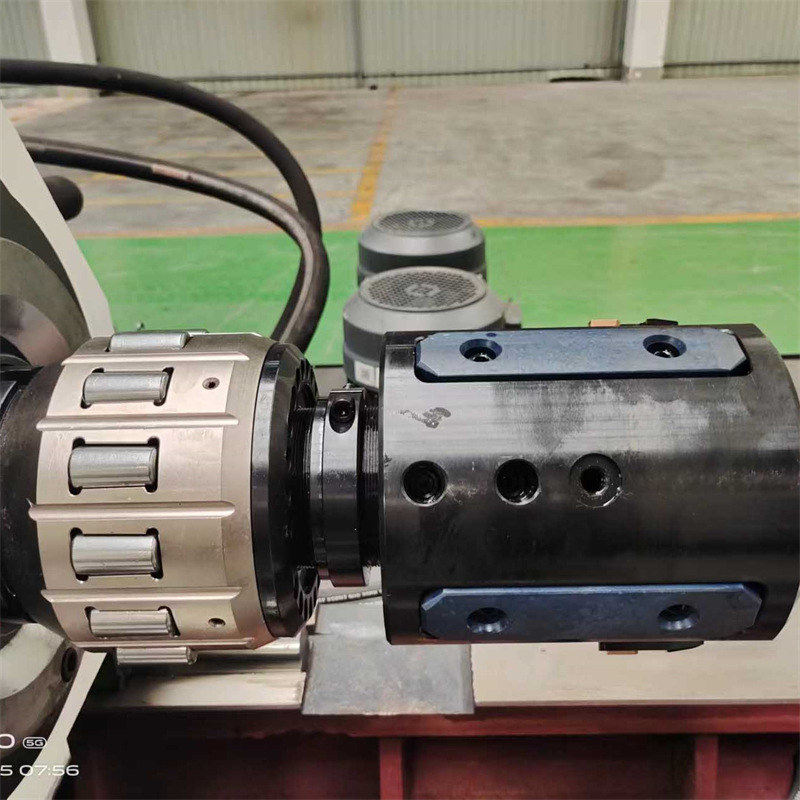

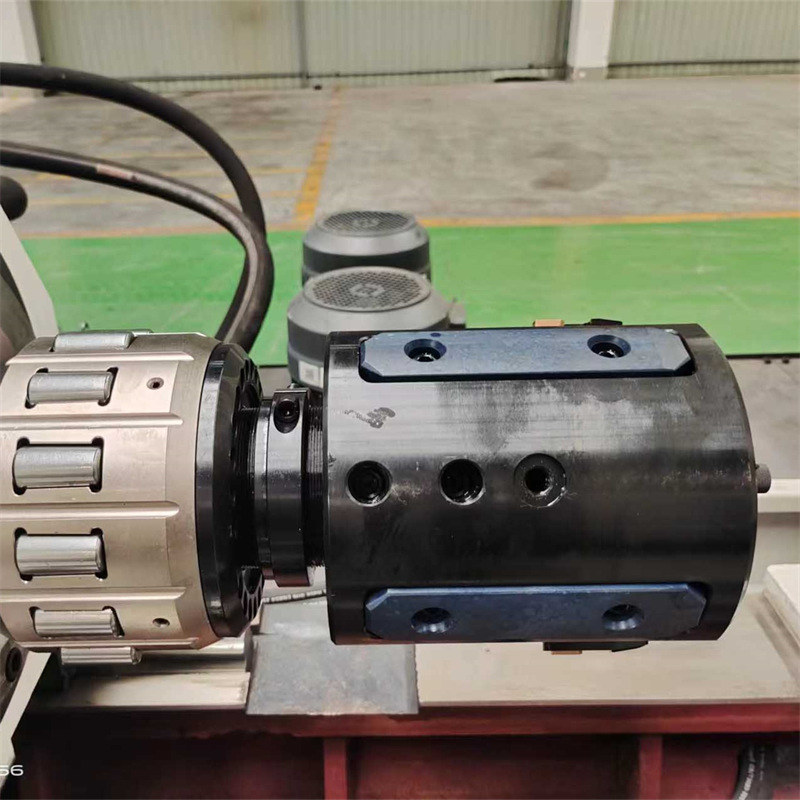

Product Pictures

All of our product photos are taken in the factory for real.

About Company

Dezhou XinHongJi CNC Machinery Co., Ltd. is mainly engaged in deep hole drilling and boring machine, scraping and boring and rolling machine.

Rich in experience

Many years of industry production experience, perfect equipment, workers mature technology

Professional customization

According to customer needs to achieve professional customization, there is always a suitable for you

Technological perfection

The introduction of mature production technology at home and abroad is a professional manufacturing enterprise

Strong strength of manufacturers

The company was established in 2017, with a modern assembly workshop, electrical assembly workshop, design center and other hardware foundation.

Rich technical experience

The company has the earliest contact and development of CNC boring and rolling machine engineering and technical personnel, with the design, installation, commissioning of many similar products experience.

Perfect after-sales service

To provide users with "complete equipment and services" is the core competitiveness of the enterprise, and strive to achieve "faster delivery time and more favorable cost performance."

Engineering case

Factory scene