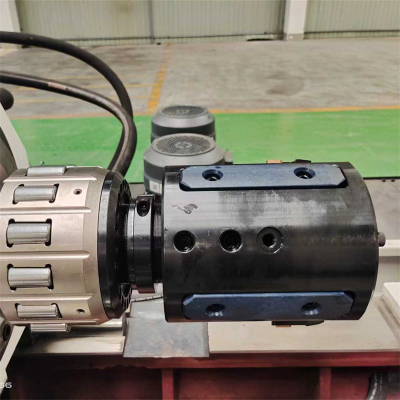

T2120g Deep Hole Drilling and Boring Machine

T2120g Deep Hole Drilling and Boring Machine is a key equipment for deep hole processing, and its characteristics mainly include the following aspects:

1. High precision machining: The T2120g Deep Hole Drilling and Boring Machine uses advanced numerical control technology, has high precision machining capabilities, and can achieve accurate machining of complex hole systems.

2. Large length-diameter ratio: The T2120g Deep Hole Drilling and Boring Machine has a large processing depth and diameter ratio, which can meet the needs of various deep hole processing, especially for the deep hole processing of long-axis parts.

3. High degree of automation: T2120g Deep Hole Drilling and Boring Machine adopts automatic control system, which can realize automatic positioning, automatic tool change, automatic measurement and other functions, greatly improving the processing efficiency and accuracy.

Product description

Regarding the operation of the T2120g Deep Hole Drilling and Boring Machine, the specific steps may include the following:

1. Prepare tools and materials: Prepare tools such as tools, blades, and drills as well as required workpieces and auxiliary materials based on the T2120g Deep Hole Drilling and Boring Machine.

2. Install the workpiece: Install the workpiece to be processed on the machine tool to ensure that the workpiece is accurately positioned and firmly fixed.

3. Input program: Write or import the corresponding processing program according to the processing requirements, and input the program into the machine tool through the CNC system.

4. Adjust parameters: Adjust the corresponding processing parameters according to the program requirements, such as tool speed, feed speed, cutting depth, etc.

5. Start processing: Start T2120g Deep Hole Drilling and Boring Machine for processing, pay attention to observe whether the processing is normal, and adjust parameters in time or stop processing if there is an anomaly.

6. Detection quality: After the processing is completed, the quality of the workpiece is tested to check whether the aperture, hole depth, surface roughness, etc., meets the requirements, and timely treatment if there is a problem.

7. Clean up the site: clean up the site, organize tools and materials, and keep the work area clean and safe.

The specific operation steps may vary due to different machine tool models and processing needs, it is recommended to consult the machine tool instruction manual or consult professional and technical personnel.

Product Pictures

All of our product photos are taken in the factory for real.

XinHongJi Advantage

Strong strength of manufacturers

The company was established in 2017, with a modern assembly workshop, electrical assembly workshop, design center and other hardware foundation.

Rich technical experience

The company has the earliest contact and development of CNC boring and rolling machine engineering and technical personnel, with the design, installation, commissioning of many similar products experience.

Perfect after-sales service

To provide users with "complete equipment and services" is the core competitiveness of the enterprise, and strive to achieve "faster delivery time and more favorable cost performance."

Engineering case

Factory scene