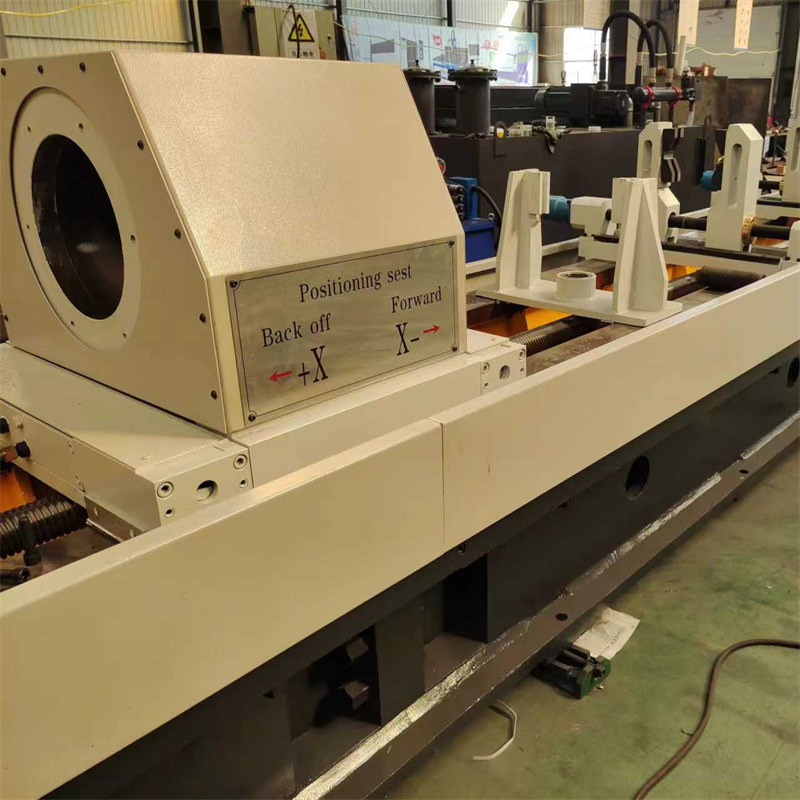

14 Meter Scraping And Rolling Machine

1. Durability: High-quality materials and manufacturing processes are often used to ensure the durability and stability of the equipment.

2. Safety: Scraping and rolling Machine is usually designed to comply with safety standards, including emergency stop devices, guards and other safety features to ensure the safety of operators.

3. Automated Controls: Advanced scraping and rolling machines are often equipped with automated control systems to increase productivity and ensure consistent quality.

14 Meter Scraping And Rolling Machine is appropriate for processing cylindrical deep hole workpieces, all forms of mechanical hydraulic cylinders, cylindrical thru holes blind holes and step holes. The device is particularly suitable for dull plate machining and rolling machining, the system device adopts the uninteresting process in which the workpiece no longer moves and the dull plate rotates, the dull plate adopts the front chip removal, and the uninteresting mode is to push the dull plate plus the oiling machine to give the oil and the head of the bed to remove the chips. Rolling after pulling rolling, the utility of high-pace scraping boring rolling head, may be fairly efficient processing cylinder, a alternate within the unique boring quilting processing cylinder of the conventional manner, the production efficiency is the traditional system of 8-10 instances. the manufacturing performance is 8-10 instances better than the traditional system. it takes 4 mins to produce a cylinder of period 2000mm with a duration of ∮eighty.

Product Accessories

The 14 Meter Scraping And Rolling Machine bed is made of high quality cast iron with strong rigidity, the spindle is driven by 30KW AC servo drive with wide speed range and large torque, the feeding system is driven by 5.5KW AC servo motor, which is able to adapt to the needs of a variety of deep-hole machining process, the oil granting device is used to tighten the workpiece tightening with a hydraulic device, and the electrical system is centrally controlled by Delta PLC from Taiwan, and displayed on the TFT color touch-screen LCD, which makes the control flexible, safe and reliable. In the production is suitable for both mass production and small batch single piece production.

Product Pictures

All of our product photos are taken in the factory for real.

Photographs of products cut by a 14 Meter Scraping And Rolling Machine.

About Company

Dezhou XinHongJi CNC Machinery Co., Ltd. is mainly engaged in deep hole drilling and boring machine, scraping and boring and rolling machine. The company was established in 2017, the production of scraping and rolling machine, scraping boring and rolling machine, deep hole drilling and boring machine, has the experience in charge of design, installation, commissioning of many similar products, has the most experienced engineering and technical personnel, with a modern assembly workshop, electrical assembly workshop, design center and other hardware foundation.

Factory environment

Rich in experience

Many years of industry production experience, perfect equipment, workers mature technology

Professional customization

According to customer needs to achieve professional customization, there is always a suitable for you

Sales Countries

Payment and Transport

FAQ

Q 1: Are you a factory or a trading company?

A: We are a factory specializing in manufacturing various hydraulic equipment.

Q 2: What certificates do you have?

A: We have ISO 9001, ISO 14001, CE, SGS and TUV certificates.

Q 3: How big is the workshop?

A: It covers an area of 100,000 square meters with 15,000 square meters of floor space.

Q 4: When can I get a quote after requesting a quote?

A: Within 24 hours.

Q5 : What is the payment method?

A : T/T, L/C

Q 6: What is the delivery time?

A: Generally, 30-45 days after receipt of prepayment.

Q7: Where is your factory? How to visit?

A: Our factory is located in Dezhou City, Shandong Province, China. You can take a plane to Jinan Airport. We will pick you up there. We warmly welcome customers from home and abroad to visit us!