Deep Hole Powerful Honing Machine

The Deep Hole Powerful Honing Machine adopts the honing wheel to cut. Through the high-speed rotation and axial feed of the honing wheel, the deep hole surface can be ground and polished to meet the processing requirements of high precision and high finish.

Deep Hole Powerful Honing Machine is widely used in automotive, machinery, petroleum, chemical and other fields, for processing all kinds of materials and specifications of deep hole parts, such as engine cylinder block, hydraulic parts, pipelines and so on.

Product description

The application scenarios of Deep Hole Powerful Honing Machine mainly include the following aspects:

1. Hydraulic cylinder processing: Hydraulic cylinder is one of the most common application scenarios of Deep Hole Powerful Honing Machine. Hydraulic cylinder is an important transmission component, and its cylinder and piston need to be honed under high precision and high efficiency to ensure its sealing performance and service life. Deep Hole Powerful Honing Machine can meet the high precision requirements of hydraulic cylinder processing and improve processing efficiency.

2 Cylinder processing: cylinder is an important part of the engine and compressor and other equipment, and its processing quality directly affects the performance and service life of the equipment. The Deep Hole Powerful Honing Machine can be used to process cylinders of various materials and specifications, including cast iron, steel, etc., to improve the surface finish and accuracy of the cylinder, reduce friction resistance, and improve equipment efficiency.

3. Pipeline and pipe fitting processing: Pipeline and pipe fitting are widely used in various industrial fields, such as petroleum, chemical industry, machinery, etc. The Deep Hole Powerful Honing Machine can be used to process pipes and fittings of various materials and specifications, including steel pipe, copper pipe, aluminum pipe, etc., to improve the inner wall finish and accuracy, and ensure the smooth flow of fluid and sealing.

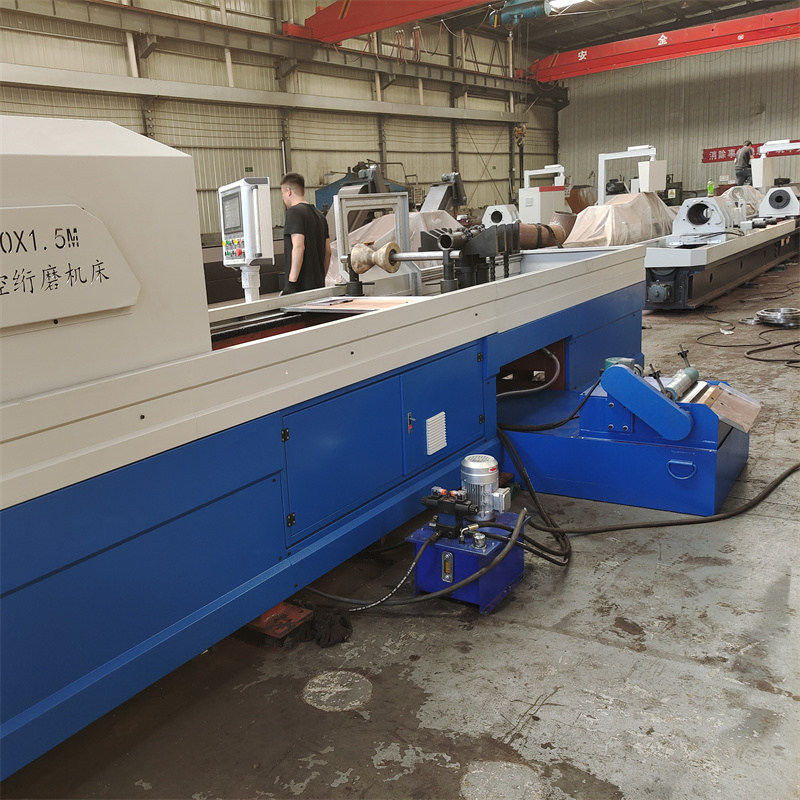

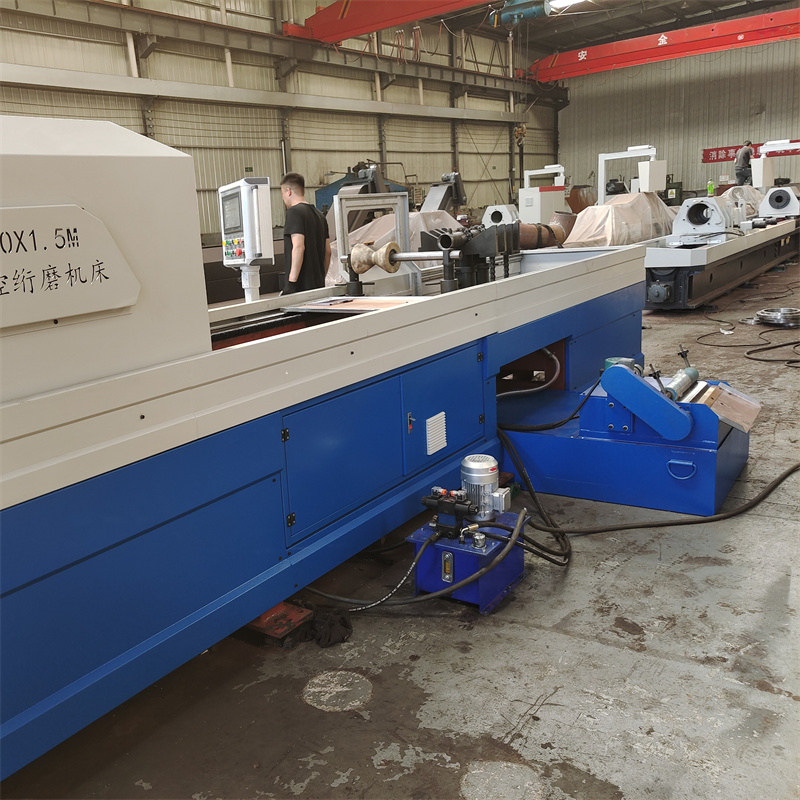

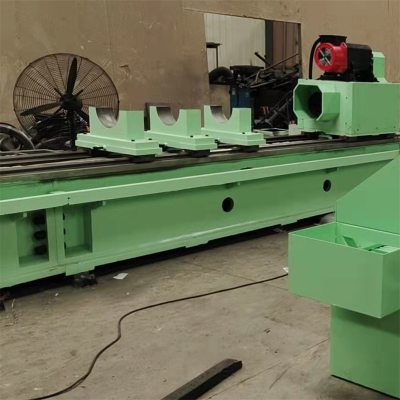

Product Pictures

All of our product photos are taken in the factory for real.

About Company

Dezhou XinHongJi CNC Machinery Co., Ltd. Mainly engaged in Skiving Roller Burnishing,Hole Boring Machine,Honing Machine manufacturing. Our company has formed a set of modern production lines, The main products are Skiving Roller Burnishing,Metal Cutting Machines,Deep Hole Drilling Machine,Honing Machine,Hole Boring Machine, etc. We assure you that we will continue to serve our customers.

Factory environment

Rich in experience

Many years of industry production experience, perfect equipment, workers mature technology

Sales Countries

Payment and Transport

FAQ

Q 1: Are you a factory or a trading company?

A: We are a factory specializing in manufacturing various hydraulic equipment.

Q 2: When can I get a quote after requesting a quote?

A: Within 24 hours.

Q 3: How big is the workshop?

A: It covers an area of 100,000 square meters with 15,000 square meters of floor space.

Q4 : What is the payment method?

A : T/T, L/C

Q 5: What is the delivery time?

A: Generally, 30-45 days after receipt of prepayment.