Deep Hole Cylinder Boring And Honing Compound Machine

Deep Hole Cylinder Boring And Honing Compound Machine is a machine used for cylindrical hole processing, which can be processed by rough boring, fine boring, honing and other processes, and has high processing accuracy. This machine is often used in the processing of cylindrical holes in automotive, aerospace, energy, medical and other industries, which can improve production efficiency and improve the quality and accuracy of holes.

The working principle of Deep Hole Cylinder Boring And Honing Compound Machine is to use a spindle with a tool or a grinding wheel to rotate the cutting or grinding inside the cylindrical workpiece, so as to obtain a pass that meets the requirements. In the Deep Hole Cylinder Boring And Honing Compound Machine, the spindle is connected to the motor through a drive shaft, the motor drives the spindle to rotate, and the feed rate of the spindle is controlled by the feed mechanism, so as to realize the machining process of the cylindrical hole.

Product description

Deep Hole Cylinder Boring And Honing Compound Machine can realize a variety of different machining processes, including rough boring, fine boring, honing, etc., in order to meet the requirements of machining different pass shapes and accuracy. At the same time, the machine also has a high rigid structure and precision control system, which can ensure the stability and accuracy of the machining process.

In general, the processing efficiency of Deep Hole Cylinder Boring And Honing Compound machines depends on a number of factors.

1. Depth and diameter of the hole: the greater the depth and diameter of the hole, the lower the processing efficiency.

2. Hardness and brittleness of the material: the higher the hardness and brittleness of the material, the more difficult the processing is, and the processing efficiency will be reduced accordingly.

3. The quality And life of the tool or grinding wheel: Deep Hole Cylinder Boring And Honing Compound Machine The better the quality of the tool or grinding wheel and the longer the life, the higher the processing efficiency.

4. Performance and accuracy of the machine: the higher the performance and accuracy of the machine, the higher the processing efficiency.

Taking these factors into consideration, the processing efficiency of Deep Hole Cylinder Boring And Honing Compound Machine is still quite high, which can improve production efficiency and reduce production costs in many processing occasions.

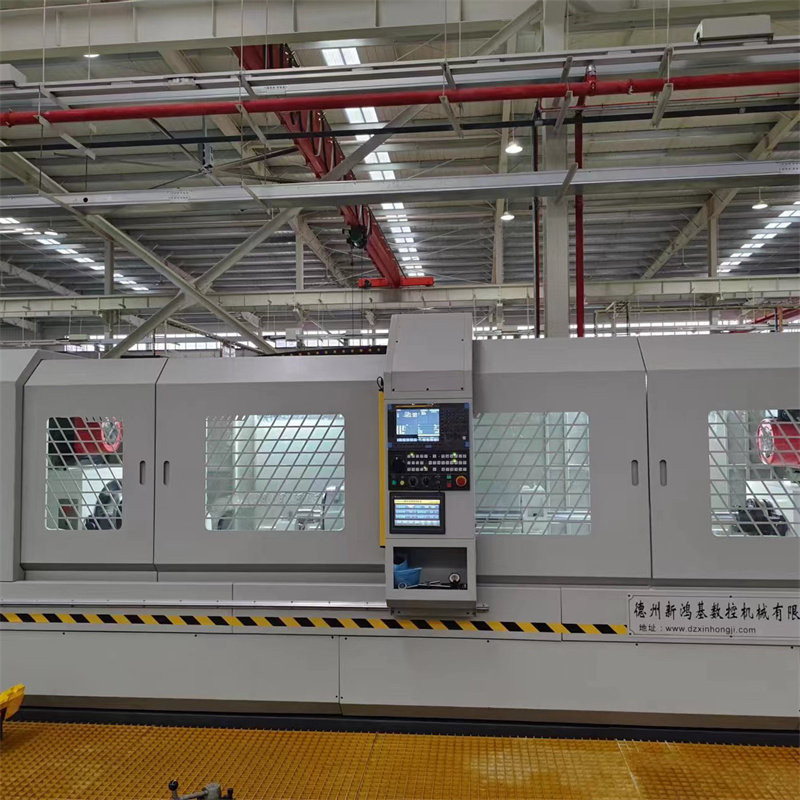

Product Pictures

All of our product photos are taken in the factory for real.

About Company

Dezhou XinHongJi CNC Machinery Co., Ltd. is mainly engaged in deep hole drilling and boring machine, scraping and boring and rolling machine.

Technological perfection

The introduction of mature production technology at home and abroad is a professional manufacturing enterprise

Strong strength of manufacturers

The company was established in 2017, with a modern assembly workshop, electrical assembly workshop, design center and other hardware foundation.

Perfect after-sales service

To provide users with "complete equipment and services" is the core competitiveness of the enterprise, and strive to achieve "faster delivery time and more favorable cost performance."

Engineering case

Factory scene