Automatic Horizontal Honing Machine

Features of Automatic Horizontal Honing Machine

High-precision machining: Automatic Horizontal Honing Machine is capable of high-precision machining of workpiece hole walls by means of a precise control system and high-quality honing tools. It can significantly improve the dimensional accuracy, shape accuracy and reduce the surface roughness (Ra value) to meet the demand of high precision machining.

Wide machining range: the machine is mainly used for hole machining, and its wide range of hole diameters can usually cover from φ5 to φ500, and the depth-to-diameter ratio can be up to 10, which makes the Automatic Horizontal Honing Machine well-adapted to a variety of applications, such as machining of cylinder holes, oil cylinder barrels, valve holes, and a variety of gun barrels, etc. The machine is also capable of machining a wide range of holes in a wide range of sizes.

Product description

Automatic Horizontal Honing Machine is a kind of high-precision CNC machine tool equipment, which is specially used for precision honing of workpiece to ensure its flatness and surface finish. Its working principle is to utilize the honing head to carry out omni-directional rotary and reciprocating honing processing on the workpiece to achieve high precision processing of the workpiece hole. Meanwhile, it is equipped with automatic measuring device and intelligent control system to ensure the stability and precision of the machining process.

Automatic Horizontal Honing Machine has the following features:

1. High precision: It can effectively improve the dimensional precision, shape precision and reduce Ra value, which can meet the quality requirements of product processing in the market.

2. Wide processing range: Automatic Horizontal Honing Machine is mainly used for hole processing, the processing hole diameter range is φ5 ~ φ500, the depth-to-diameter ratio can be up to 10, so it is widely used for processing cylinder holes, cylinder barrels, valve holes and many kinds of barrels, etc., in mass production, and it can be used for single-piece small batch production.

3. High efficiency: Compared with other grinding equipment, honing has the characteristics of reducing workers' physical labor, high productivity and easy to realize automation.

4. Convenient maintenance: The structure of Automatic Horizontal Honing Machine is reasonably designed and easy to maintain. Its main components such as honing head, spindle, etc. can be easily replaced and repaired, reducing maintenance costs and maintenance time.

5. Stable machining process: Through the automatic measuring device and control system, Automatic Horizontal Honing Machine can monitor the machining process in real time and adjust the machining parameters automatically according to the machining situation. This ensures the stability of the machining process and the reliability of the machining quality.

Overall, Automatic Horizontal Honing Machine has a wide range of application prospects in the field of machining due to its high precision, high efficiency and high degree of automation.

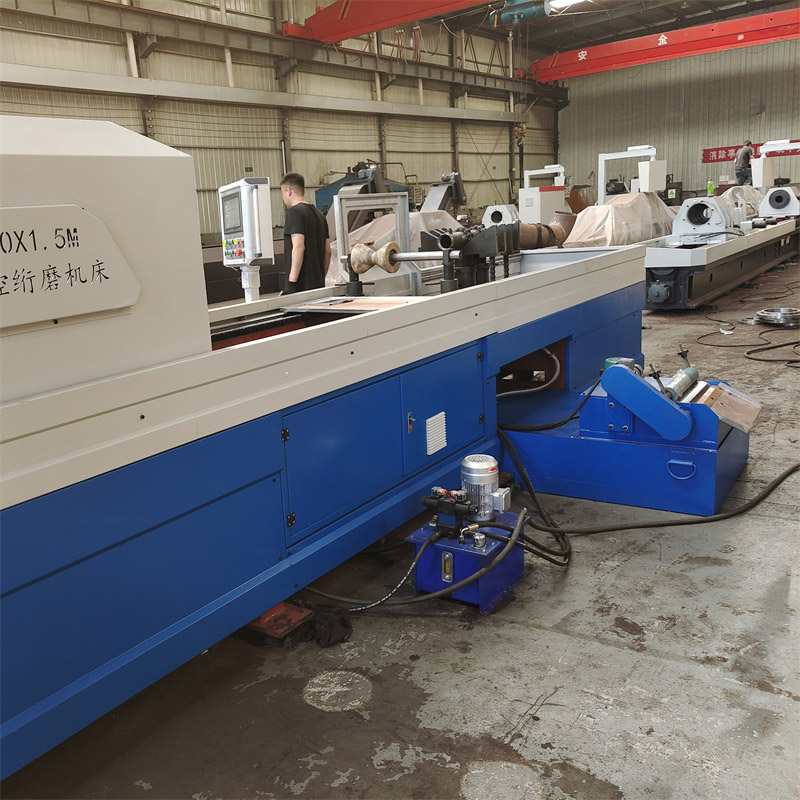

Product Pictures

About Company

Dezhou XinHongJi CNC Machinery Co., Ltd. Mainly engaged in Skiving Roller Burnishing,Hole Boring Machine,Honing Machine manufacturing.

We assure you that we will continue to serve our customers.

Engineering case

Payment and Transport