Deep Hole Tool

The Deep Hole Tool is a tool specially used for deep hole machining, which is characterized by small diameter and large length, and can be used for machining holes with a large ratio of hole depth to aperture. The material, structure and processing technology of Deep Hole Tool are different from ordinary tools, so its use and maintenance also have certain special requirements.

Product description

The materials of Deep Hole Tool are generally made of hard alloy, ceramics, cubic boron nitride and other materials with high hardness and high wear resistance to withstand high temperature and friction and wear in deep hole machining. At the same time, the geometric parameters and structural design of Deep Hole Tool are also its special features, which need to be selected and adjusted according to different processing requirements.

Note the following points when using the Deep Hole Tool:

1. Select the appropriate cutting parameters, such as cutting speed, feed rate, cutting depth, etc., to avoid excessive tool wear or damage.

2. Check the Tool before use to ensure that the Deep Hole Tool has no cracks, wear, etc., and check whether the tool is correctly installed and securely fastened.

3. The coolant needs to be kept sufficient and clean during processing to reduce tool wear and heat generation.

4. It is necessary to clean and maintain the tool after processing, and replace the worn blade or tool head in time.

In short, Deep Hole Tool is a high-precision and high-efficiency processing tool. Proper use and maintenance can extend its service life and improve processing quality and efficiency. For more information on deep hole tools, it is recommended to consult a professional.

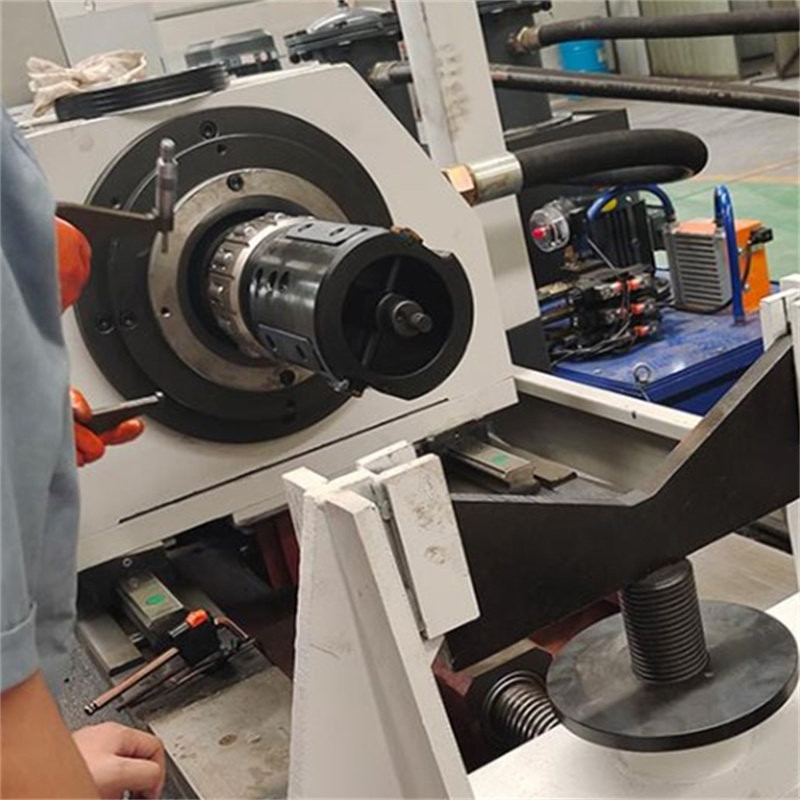

Product Pictures

All of our product photos are taken in the factory for real.

Corporate advantage

Strong strength of manufacturers

The company was established in 2017, with a modern assembly workshop, electrical assembly workshop, design center and other hardware foundation.

Rich technical experience

The company has the earliest contact and development of CNC boring and rolling machine engineering and technical personnel, with the design, installation, commissioning of many similar products experience.

Perfect after-sales service

To provide users with "complete equipment and services" is the core competitiveness of the enterprise, and strive to achieve "faster delivery time and more favorable cost performance."

Engineering case

Factory scene