Deep Hole Forming Tool

The advantages of Deep Hole Forming Tool are as follows:

1. High efficiency: The processing speed of Deep Hole Forming Tool is fast, and a large number of processing work can be completed in a short time, improving production efficiency.

2. High precision: The tool can process high-precision holes to meet the manufacturing requirements of various parts.

3. Good surface quality: Deep Hole Forming Tool can produce holes with good surface quality, improving the service life and reliability of parts.

4. High safety: The machining process of the tool is carried out in a closed environment, reducing the harm to the human body during the processing.

In short, Deep Hole Forming Tool has the advantages of high efficiency, high precision, good surface quality, wide application range and high safety, so it has been widely used in the manufacturing industry.

Product description

Deep Hole Forming Tool is a machine for machining deep holes (more than 3 times the diameter) on large parts such as aircraft parts, automotive parts, etc. It can be single-axis or multi-axis, enabling efficient machining of precision deep holes. Deep Hole Forming tools are often used in aerospace, automotive manufacturing, energy exploration and other fields.

Deep Hole Forming Tool works by removing material in turn on a cylindrical workpiece with a series of tools to create a hole with a specific diameter and depth. When the tool is fed along the axis of the workpiece, the rotary motion of the tool is combined with the feed motion, so that the tool cuts the workpiece at a certain depth, thus continuously forming a hole. In the process of deep hole forming, in order to protect the tool and ensure the quality of the machining, it is usually necessary to use coolant to cool and lubricate the tool.

Deep Hole Forming Tool is mainly used in aerospace, aviation, automotive, mold, energy and other manufacturing industries. Some specific applications of Deep Hole Forming Tool are as follows:

1. Aerospace: Deep Hole Forming Tool can make deep holes in aircraft engine parts, such as nozzles, combustion chambers, etc.

2. Automotive manufacturing: Tappet, cylinder, oil pan, etc. in automotive engines also need to use deep-hole forming tools for processing.

3. Mold manufacturing field: Deep Hole Forming Tool can manufacture plastic molds, die casting molds, etc., for the production of plastic products and metal products of various shapes.

4. In the field of energy exploration: Deep Hole Forming Tool can manufacture wellbore and drill pipe in oil and gas exploitation.

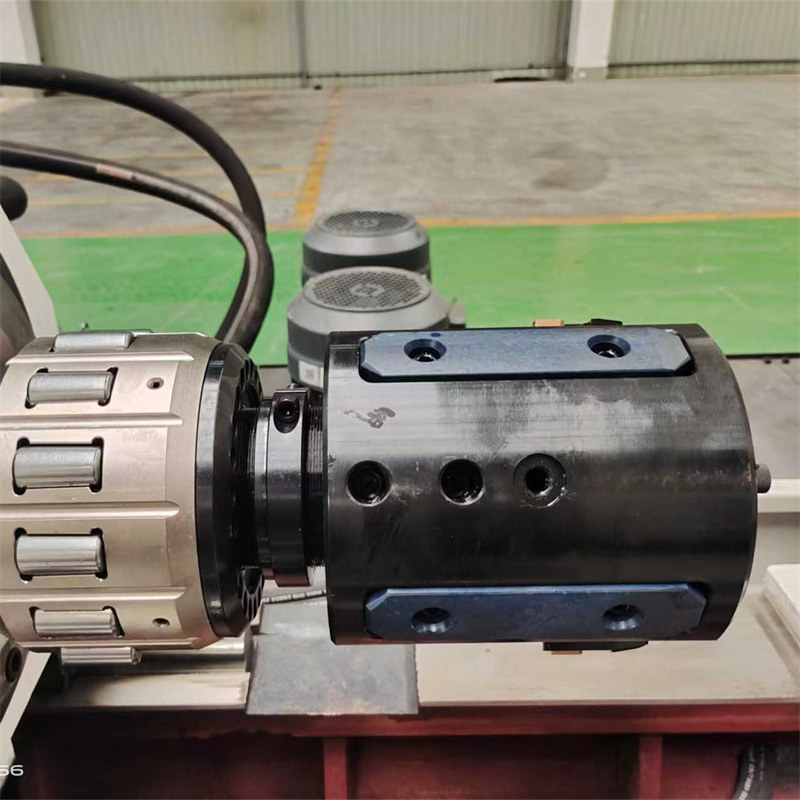

Product Pictures

All of our product photos are taken in the factory for real.

About Company

Dezhou XinHongJi CNC Machinery Co., Ltd. is mainly engaged in deep hole drilling and boring machine, scraping and boring and rolling machine.

Professional customization

According to customer needs to achieve professional customization, there is always a suitable for you

Strong strength of manufacturers

The company was established in 2017, with a modern assembly workshop, electrical assembly workshop, design center and other hardware foundation.

Perfect after-sales service

To provide users with "complete equipment and services" is the core competitiveness of the enterprise, and strive to achieve "faster delivery time and more favorable cost performance."

Engineering case

Factory scene

The company has great technical strength in the production of deep hole tools and auxiliary tools, which effectively ensures the compatibility of the machine tool and reduces the user's use cost.