Deep Hole Drilling Tool

Deep Hole Drilling Tool is a tool specifically designed for deep hole machining in the machining industry. It is usually composed of a tool bar, a tool head and a guide sleeve, and the tool head has a certain spiral Angle to ensure chip removal and cutting efficiency. The guide sleeve is used to ensure that the tool does not shift during machining, ensuring machining accuracy. Deep hole drilling tool is commonly used for deep hole machining in automotive manufacturing, aerospace, energy and other fields.

Product description

The service life of Deep Hole Drilling Tool can be extended by:

1. Choose the right tool material: Different materials are suitable for different cutting conditions. Choosing materials with better hardness and wear resistance can extend the service life of the tool.

2. Reasonable arrangement of processing technology: optimizing cutting parameters, such as cutting speed, feed rate, cutting depth, etc., can reduce tool wear and improve processing efficiency.

3. Maintain the supply of coolant: the coolant can reduce the temperature of the tool, avoid the thermal deformation of the tool, thereby extending the service life of the tool.

4. Regularly check the wear of the tool: regularly check the wear of the Deep Hole Drilling Tool and replace the worn tool in time, which can avoid excessive wear of the tool and extend the service life of the tool.

5. Improve the processing accuracy: by choosing higher precision machine tools and processing technology, improve the processing accuracy, reduce the grinding and impact of the tool, thus extending the service life of the tool.

In short, through the comprehensive consideration of the above factors, the service life of Deep Hole Drilling Tool can be extended, and the processing efficiency and quality can be improved.

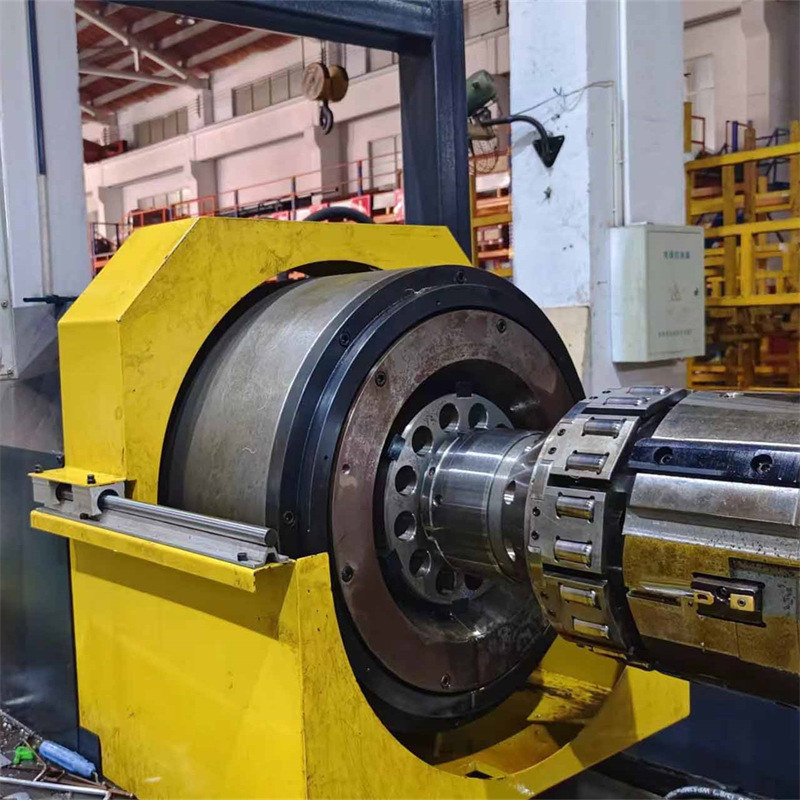

Product Pictures

All of our product photos are taken in the factory for real.

About Company

Dezhou XinHongJi CNC Machinery Co., Ltd. is mainly engaged in deep hole drilling and boring machine, scraping and boring and rolling machine.

Strong strength of manufacturers

The company was established in 2017, with a modern assembly workshop, electrical assembly workshop, design center and other hardware foundation.

Rich technical experience

The company has the earliest contact and development of CNC boring and rolling machine engineering and technical personnel, with the design, installation, commissioning of many similar products experience.

Perfect after-sales service

To provide users with "complete equipment and services" is the core competitiveness of the enterprise, and strive to achieve "faster delivery time and more favorable cost performance."

Engineering case

Factory scene