Deep Hole Cutting Head

The Deep Hole Cutting Head is a tool used for deep hole machining. It usually consists of a cemented carbide cutter head and a gripper. In Deep Hole machining, the Deep Hole Cutting Head can be drilled, milled or rotated to penetrate metal materials and form a predetermined shape in the hole. The design of the Deep Hole Cutting Head is very important because it needs to withstand high pressure and temperature while maintaining high accuracy. Different Deep Hole Cutting heads can be adapted to different applications and materials. For example, some Deep Hole Cutting heads are suitable for high-speed machining, while others are suitable for machining hard materials.

Product description

Here are some suggestions on the proper use of a Deep Hole Cutting Head:

1. Follow the manufacturer's recommendations: Before using the Deep Hole Cutting Head, be sure to read the manufacturer's instruction manual and follow their recommendations.

2. Choose the right tool: Choose the right tool according to the nature of the material to be cut and the required cutting performance.

3. Install the Cutting Head: Ensure that the Deep Hole Cutting Head is compatible with the cutting equipment and is properly installed on the cutting equipment.

4. Adjust the height and Angle of the Deep Hole Cutting Head: Adjust the height and Angle of the deep hole cutting head as required.

5. Control cutting speed and feed rate: the cutting speed and feed rate should be properly adjusted to ensure the best cutting effect.

6. Maintenance of Deep Hole Cutting Head: Regular cleaning and maintenance to ensure that it is in good condition and extend its service life.

Here are some Deep Hole Cutting Head maintenance methods:

1. Check the Deep Hole Cutting Head before processing: Before using the product, it needs to be inspected to ensure that it is not worn and damaged. If the Deep Hole Cutting Head is found to be faulty, it needs to be replaced immediately.

2. Keep the Cutting Head clean: During the processing, the Deep Hole Cutting Head will be affected by cutting heat and cutting metal, so it needs to be kept clean. Dry air or nitrogen can be used to purge to remove cutting metal and dust.

3. Use the correct Cutting parameters: When using the Deep Hole Cutting Head, use the correct cutting parameters. For example, cutting speed, feed speed and cutting depth all affect the life of the cutting head.

4. Avoid excessive wear: In the processing process, it is necessary to avoid excessive wear of Deep Hole Cutting Head. Wear on the cutting head can be reduced by controlling the cutting depth and feed speed.

5. Replace the Cutting Head regularly: The life of the Deep Hole Cutting Head is limited, so it needs to be replaced regularly. In general, after processing a certain number of parts, they need to be replaced regularly.

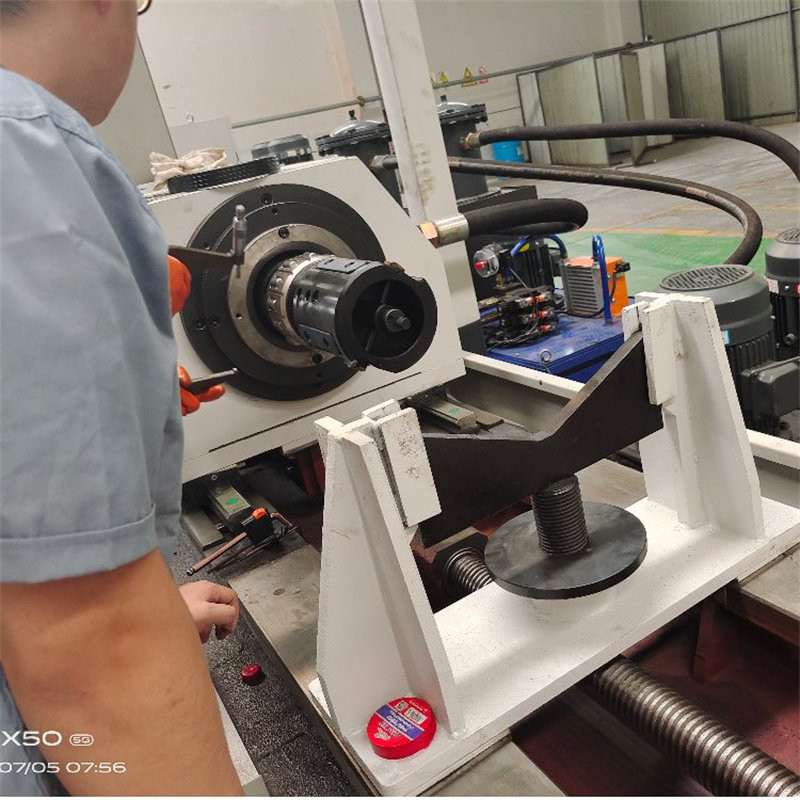

Product Pictures

All of our product photos are taken in the factory for real.

About Company

Dezhou XinHongJi CNC Machinery Co., Ltd. is mainly engaged in deep hole drilling and boring machine, scraping and boring and rolling machine.

Strong strength of manufacturers

The company was established in 2017, with a modern assembly workshop, electrical assembly workshop, design center and other hardware foundation.

Rich technical experience

The company has the earliest contact and development of CNC boring and rolling machine engineering and technical personnel, with the design, installation, commissioning of many similar products experience.

Perfect after-sales service

To provide users with "complete equipment and services" is the core competitiveness of the enterprise, and strive to achieve "faster delivery time and more favorable cost performance."

Engineering case

Factory scene