Working Principle Of Honing Machine

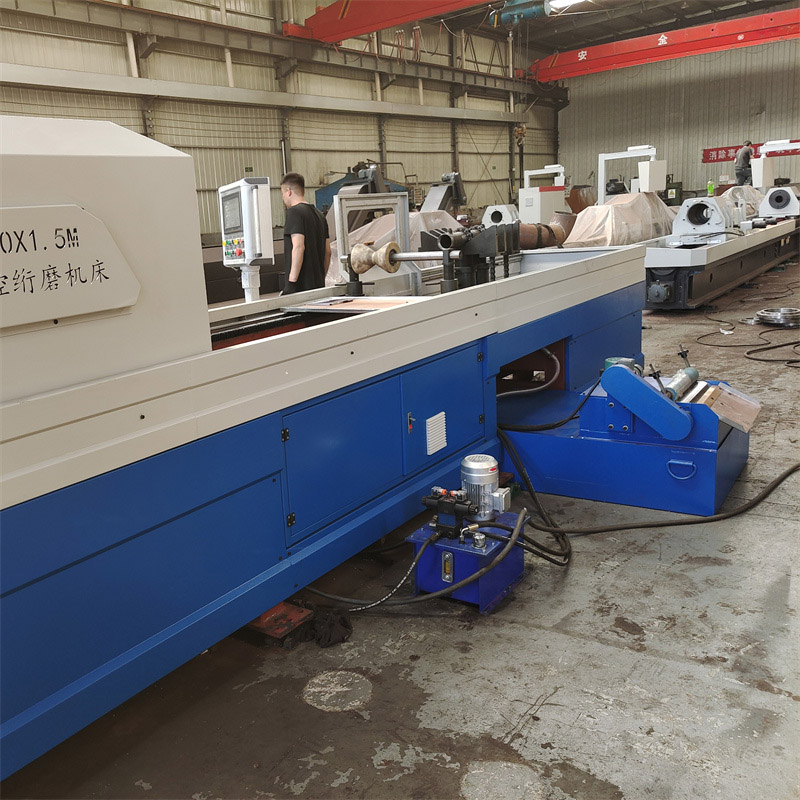

Honing Machine is a kind of equipment used for precision machining of the inner surface of cylinder holes, bearing holes and other parts. Its working principle mainly includes the following steps:

1. Clamping workpiece: First of all, the workpiece that needs to be processed is installed on the honing machine and fixed by the clamping device to ensure the stability and accuracy of the workpiece during processing.

2. Grinding stone installation: The grinding wheel is installed on the Honing Machine, which is usually a grinding head composed of several pieces of sand and stone. These sands usually have different roughness and are used to achieve precision machining of the inner hole surface of the workpiece.

3. Lubrication and cooling: In the process of processing, the cutting fluid is sprayed to the surface of the workpiece through the spray system, which can both play a lubricating role and cool the workpiece and the grinding head to prevent overheating and reduce friction.

4. Grinding processing: Start the Honing Machine, the grinding wheel begins to rotate and grind reciprocally on the workpiece surface. Because the grinding wheel is constantly moving along the workpiece axis, it is possible to achieve uniform machining of the entire hole wall surface.

5. Remove burrs: The grinding action of the grinding wheel will remove burrs and irregular parts on the inner surface of the workpiece, making the surface more smooth.

Through these steps, the Honing Machine can perform precision machining on the surface of the inner hole of the workpiece, improve its dimensional accuracy and surface quality, and is suitable for parts processing requiring high precision, smoothness and roundness.