Honing Tools For CNC Machines

Application of honing tools in CNC machine tools

Honing Tools For CNC Machines are widely used in various precision manufacturing fields, such as aerospace, automotive manufacturing, mold manufacturing and so on. Specific applications include:

1. Inner hole processing: honing tools can be used to process inner holes of various shapes and sizes, such as engine blocks, bearing holes, etc. By precisely controlling the movement track and speed of the honing head, the inner hole surface can be machined with high precision.

2. Plane machining: Honing Tools For CNC Machines can also be used for plane machining, such as molds, precision parts, etc. By adjusting the Angle and force of the honing head, the flat surface can be processed uniformly and the surface quality can be improved.

Product description

With the rapid development of manufacturing industry, the demand for precision machining technology is increasing day by day. As the core equipment of modern manufacturing industry, the precision and efficiency of CNC machine tool directly affect the product quality and production efficiency. In this context, Honing Tools For CNC Machines, as an efficient CNC machine tool accessories, is gradually becoming an indispensable part of the manufacturing industry.

First, the principle of honing tools

Honing Tools For CNC Machines is a kind of tool for machining the workpiece surface with high precision by means of cutting, extrusion and polishing by using the relative motion between the abrasive particle and the workpiece surface. It is mainly composed of honing head, honing rod and driving device. The honing head is equipped with abrasive particles, which can realize fine machining of the workpiece surface through high-speed rotation and reciprocating movement.

Second, the development trend of Honing Tools For CNC Machines

With the increasing demand for high-precision and high-efficiency processing technology in the manufacturing industry, honing tools are also constantly developing and innovating. In the future, honing tools will develop in the following directions:

1. Intelligent: With the help of advanced sensors and control systems, to achieve intelligent processing of honing tools. Through real-time monitoring of various parameters in the machining process, such as temperature, pressure, speed, etc., the adaptive adjustment and optimization of the machining process are realized.

2. Compound: the honing tool is combined with other processing technologies to form a composite processing system. By integrating a variety of processing methods, the workpiece can be fully and efficiently processed, and the processing efficiency and quality can be improved.

3. Green environmental protection: In the design and manufacturing process of honing tools, pay attention to environmental protection and energy saving. Environmentally friendly materials and processes are used to reduce energy consumption and emissions during processing and achieve green manufacturing.

In short, as an important tool of modern manufacturing industry, Honing Tools For CNC Machines are injecting new vitality into the development of manufacturing industry with its high-precision and high-efficiency characteristics. With the continuous progress of technology and the continuous expansion of application fields, honing tools will play a more important role in the future, promoting the manufacturing industry to a higher level.

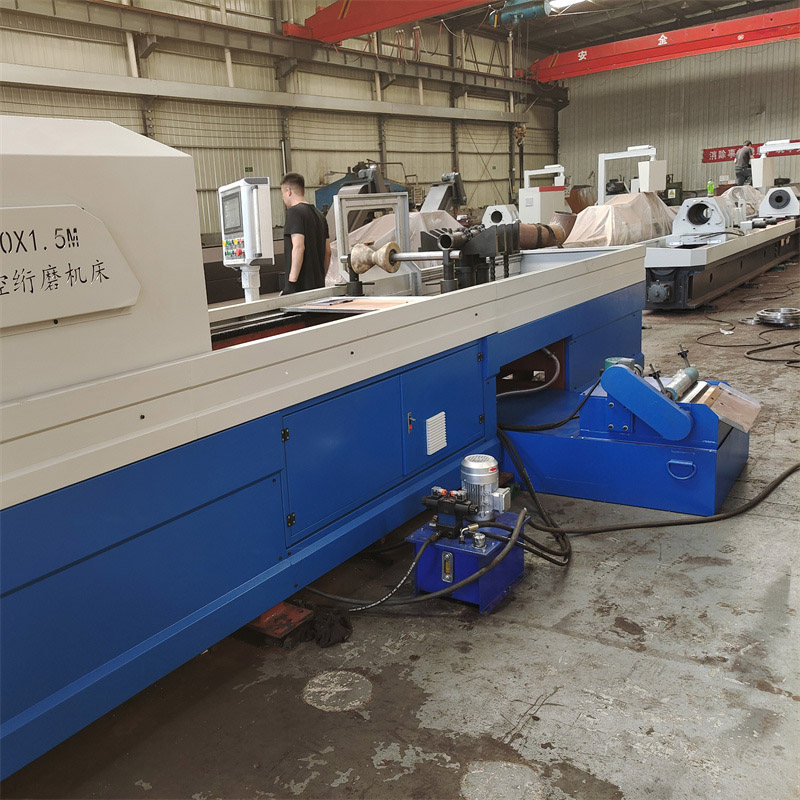

Product Pictures

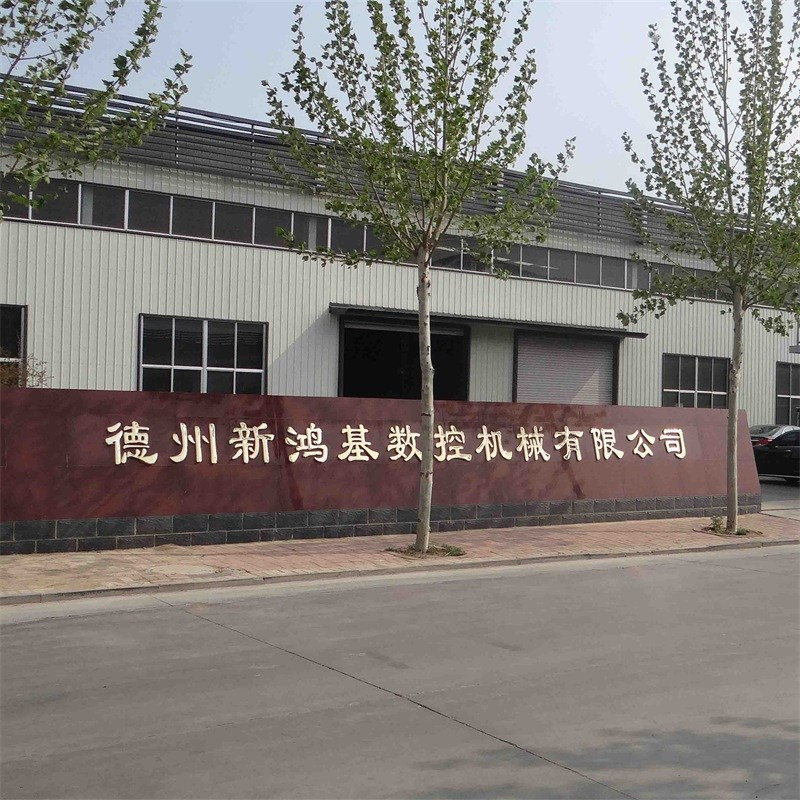

About Company

Dezhou XinHongJi CNC Machinery Co., Ltd. Mainly engaged in Skiving Roller Burnishing,Hole Boring Machine,Honing Machine manufacturing.

We assure you that we will continue to serve our customers.

Engineering case

Payment and Transport

FAQ

Q: What are the advantages of Honing Tools For CNC Machines?

A: Honing tools can achieve micron machining accuracy, improve surface quality, while processing speed, improve production efficiency.

Q: What are your honing tools for?

A: Our Honing Tools For CNC Machines are widely used in aerospace, automotive manufacturing, mold manufacturing and other fields requiring high-precision machining.

Q: How does your company guarantee the quality of honing tools?

A: We adopt a strict quality control system, from raw material procurement to finished products, each link is strictly tested and screened to ensure stable and reliable product quality.