CNC High Efficiency Deep Hole Horizontal Honing Machine

CNC High Efficiency Deep Hole Horizontal Honing Machine product advantages

Strong adaptability: can adjust the processing parameters according to different processing requirements, such as feed speed, grinding wheel speed, etc., suitable for a variety of materials and aperture size processing tasks.

Easy to operate: the human-machine interface is friendly, the operator can easily input processing instructions through the touch screen, and the control system automatically completes the corresponding processing process.

Product description

CNC High Efficiency Deep Hole Horizontal Honing Machine is an advanced machining equipment, specially designed for high-precision deep hole machining, widely used in aviation, automotive, machinery manufacturing and other industries. The machine combines modern numerical control technology and deep hole honing technology, which can efficiently and accurately complete the deep hole machining of various complex workpieces.

Main feature

High precision machining

The machine adopts high quality servo motor and high rigidity guide rail system to ensure the accuracy and stability in the machining process. Its positioning accuracy can reach the micron level, which is suitable for machining parts with high tolerances.

Numerical control system

The advanced numerical control system makes the operation easier, and the user can quickly adjust the machining parameters through programming to adapt to the needs of different workpieces. At the same time, the system supports graphical interface, which is convenient for operators to carry out real-time monitoring and data recording.

Strong cutting ability

The machine is equipped with efficient honing tools to improve cutting efficiency while ensuring surface finish. Deep holes can be processed up to several meters deep to meet the needs of most industrial applications.

Application field

CNC High Efficiency Deep Hole Horizontal Honing Machine is widely used in the machining of engine cylinder, hydraulic cylinder, oil well pipe and other deep hole parts. Its excellent performance makes it an indispensable and important equipment in modern manufacturing, helping enterprises to improve production efficiency and product quality.

Sum up

In short, CNC High Efficiency Deep Hole Horizontal Honing Machine, with its high precision, high efficiency and automation characteristics, meets the strict requirements of modern industry for deep hole processing, and provides strong technical support for various industries.

Product Pictures

About Company

Dezhou XinHongJi CNC Machinery Co., Ltd. Mainly engaged in Skiving Roller Burnishing,Hole Boring Machine,Honing Machine manufacturing.

We assure you that we will continue to serve our customers.

Engineering case

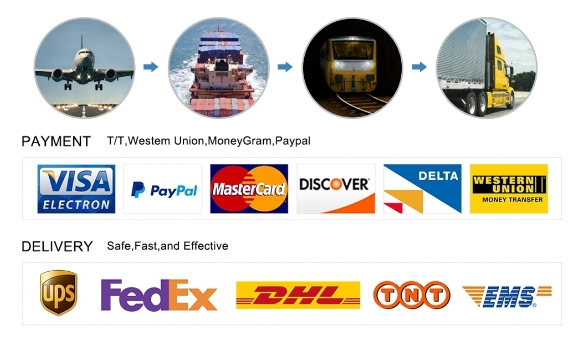

Payment and Transport