Fine Boring Head

1. Accuracy and Precision: Precision boring heads are designed to achieve high precision machining, ensuring dimensional accuracy and surface quality of the bore.

2. Adjustability: Bits typically have adjustable features that allow parameters such as diameter and depth to be adjusted to suit different machining requirements and bore sizes.

3. Stability and Rigidity: Designed for stability and rigidity to ensure accuracy and stability at high machining speeds.

4. Multiple Tool Configuration: Some precision boring heads can be configured with multiple tools for simultaneous machining of multiple holes to improve efficiency.

1. Machining method:

The front end of the system is the fine boring head, equipped with 2-3 sets of precision machine-clamped indexable inserts and 2-3 sets of carbide guide blocks. Rough boring head is mainly to remove most of the cutting material, followed by floating scraping head, scraping head is mainly to reduce or eliminate the wave marks and errors on the surface of the bore before machining, the last side of the system is the rolling head, equipped with 6-40 grains of rollers, extruding the inner wall of the cylinder block, so that the surface becomes smoother and form a better surface profile after the completion of scraping. After the product is processed, the hydraulic control retracts the scraping blade, tracking guide block and rolling head back at the same time to prevent scratching the surface of the workpiece.

2. Characteristics of super system:

Can process seamless cold-drawn pipe, welded cold-drawn pipe, as well as hot-rolled steel pipe, cast steel pipe.

Can easily and quickly adjust the size of the tool, guide block and rolling mechanism, respectively. After the system is finished processing, through hydraulic control, the scraping cutter seat, guide block and rolling parts are synchronously retracted, thus the system as a whole can be quickly retracted and ensure that the processed surface will not be damaged.

Adopting high-efficiency combination design, TTXG also integrates the triple process of rough boring, fine boring, rough scraping, fine scraping and rolling five procedures, which can complete the machining of large-remaining steel pipe at one time, greatly improving the machining efficiency, which is more than 20 times of the traditional honing. Meanwhile the tool life is longer.

The surface hardness of the product is increased by about 30% after processing. The precision can reach above IT80 grade, and the surface roughness can reach Ra0.05-0.2um.

Improve the matching precision, reduce wear and prolong the service life of the parts, the cylinder is anti-corrosion and wear-resistant after rolling, and the surface is smooth as a mirror, which can improve the service life of the sealing ring or seals.

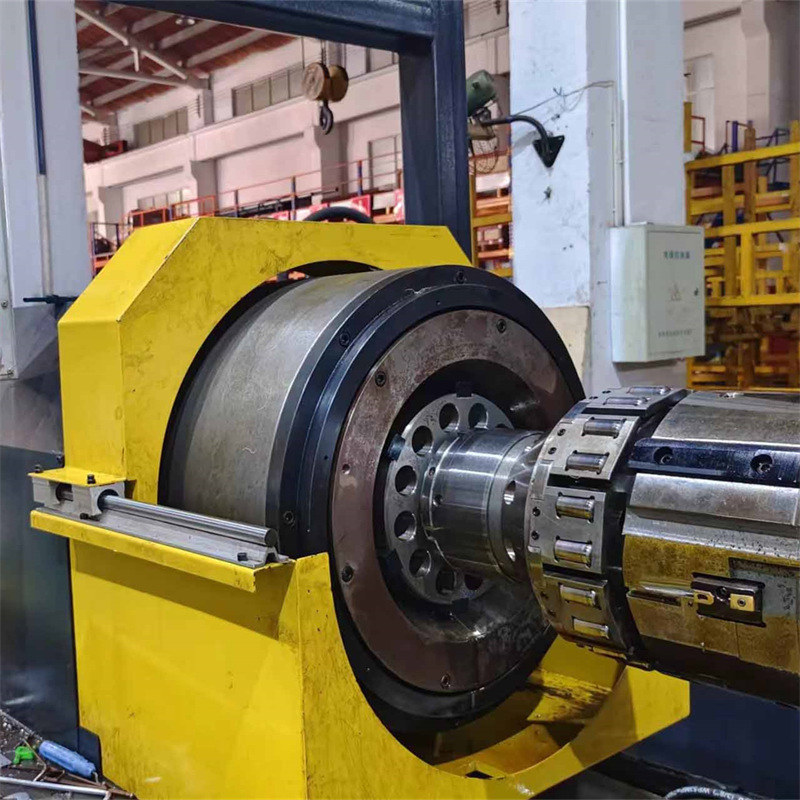

Product Pictures

All of our product photos are taken in the factory for real.

About Company

Dezhou XinHongJi CNC Machinery Co., Ltd. Established in 2017, the production of Skiving Roller Burnishing,Metal Cutting Machines,Deep Hole Drilling Machine, with the experience in charge of design, installation, commissioning of multiple similar products with a modern assembly workshop, Electrical assembly workshop, design center and other hardware foundation.

Factory environment

Now the company's products have been widely used in the world, well received by users! To provide users with "complete equipment and services" is the core competitiveness of the enterprise, in addition, our company from the user's point of view, and strive to achieve "fast delivery time, preferential cost performance."

XinHongJi is your ideal choice, XinHongJi is your trusted partner!

Sales Countries

Payment and Transport

FAQ

Q 1: Are you a factory or a trading company?

A: We are a factory specializing in manufacturing various hydraulic equipment.

Q 2: When can I get a quote after requesting a quote?

A: Within 24 hours.

Q 3: What is the delivery time?

A: Generally, 30-45 days after receipt of prepayment.

Q 4: Where is your factory? How to visit?

A: Our factory is located in Dezhou City, Shandong Province, China. You can take a plane to Jinan Airport. We will pick you up there. We warmly welcome customers from home and abroad to visit us!