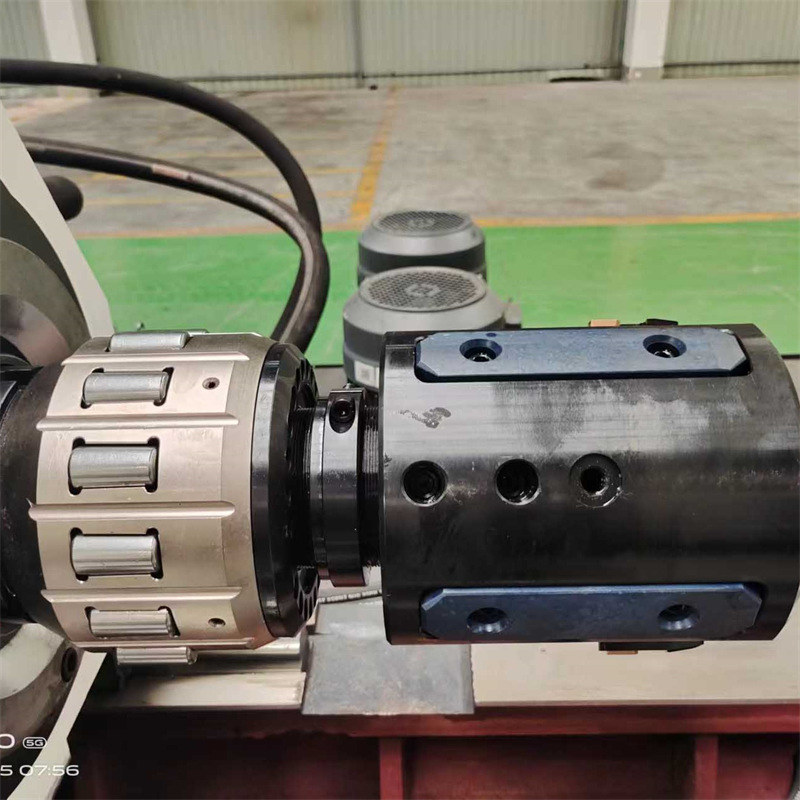

Deep Hole Rough Boring Head

The structure of Deep Hole Rough Boring Head includes tool holder, cutter head and blade. The tool bar is the main part of the Deep Hole Rough Boring Head, which is used to connect the spindle of the machine tool and the cutter head to transfer the cutting force; The cutter Head is the core part of the Deep Hole Rough Boring Head, which is used to install the blade and control the cutting direction and amount; The blade is the cutting part of the Deep Hole Rough Boring Head and is used to make direct contact with the workpiece to complete the cutting work.

Product description

The Deep Hole Rough Boring Head is a tool for deep hole machining, whose role is to rough the blank of the deep hole to the desired diameter and shape accuracy. Deep Hole Rough Boring Head has good cutting performance and machining accuracy, which can meet the processing requirements of high efficiency and high quality.

Deep Hole Rough Boring Head plays a vital role in deep hole machining. First, the Deep Hole Rough Boring Head can improve processing efficiency. Thanks to its efficient cutting method and high cutting speed, the Deep Hole Rough Boring Head is able to significantly reduce processing time and improve production efficiency. Second, Deep Hole Rough Boring Head can guarantee the quality of processing. Its high-precision manufacturing process and reliable blade clamping method can ensure the stability and accuracy in the cutting process, so as to obtain high-quality machining results. In addition, the deep hole rough boring head also has good durability and reliability, which can ensure long-term stable service life and low failure rate.

In short, the Deep Hole Rough Boring Head is an efficient, high-precision, high-reliability tool, widely used in machining, petrochemical, aerospace and other fields of deep hole processing. With the continuous advancement of science and technology and the continuous improvement of processing requirements, the technical performance and manufacturing process of Deep Hole Rough Boring Head are also constantly improved and perfected to adapt to more complex and harsh processing environments.

Product Pictures

All of our product photos are taken in the factory for real.

About Company

Dezhou XinHongJi CNC Machinery Co., Ltd. Established in 2017, the production of Skiving Roller Burnishing,Metal Cutting Machines,Deep Hole Drilling Machine, with the experience in charge of design, installation, commissioning of multiple similar products with a modern assembly workshop, Electrical assembly workshop, design center and other hardware foundation.

Factory environment

Perfect after-sales service

To provide users with "complete equipment and services" is the core competitiveness of the enterprise, and strive to achieve "faster delivery time and more favorable cost performance."

Sales Countries

Payment and Transport

FAQ

Q 1: What is the delivery time?

A: Generally, 30-45 days after receipt of prepayment.

Q 2: How big is the workshop?

A: It covers an area of 100,000 square meters with 15,000 square meters of floor space.

Q 3: When can I get a quote after requesting a quote?

A: Within 24 hours.

Q 4 : What is the payment method?

A : T/T, L/C

Q5: Where is your factory? How to visit?

A: Our factory is located in Dezhou City, Shandong Province, China. You can take a plane to Jinan Airport. We will pick you up there. We warmly welcome customers from home and abroad to visit us!