Cylinder Boring And Honing Machine

The installation of the Cylinder Boring And Honing Machine includes steps such as selecting a suitable location, preparing the foundation, installing the base and main machine, connecting power and air sources, adjusting and calibrating, installing accessories and accessories, performing safety checks, and starting the machine. During the installation, strictly follow the installation manual and standards to ensure the safety and normal operation of the machine.

Product description

Cylinder Boring And Honing Machine is a mechanical device for machining internal holes. It is suitable for all types of cylinders, cylinders and other cylindrical parts. It can carry out two steps of boring and honing in one machining, thus improving the machining quality and efficiency.

The Cylinder Boring And Honing Machine works by mounting a cylindrical part on a jig and then machining the inner hole of the part with a diamond boring head and honing bar that rotate at high speed. During the machining process, cutting fluid is introduced into the cutting area to cool and lubricate the machined surface and carry the chips away.

Cylinder Boring And Honing Machine can improve machining accuracy, reduce surface roughness, and improve the surface quality and wear resistance of parts. Therefore, it is widely used in automotive, aerospace and other industries.

Product Pictures

Product installation

Install Cylinder Boring And Honing Machine as follows:

1. Select a smooth and stable ground as the installation position.

2. Prepare the machine foundation according to the installation manual.

3. Install the base and ensure that it is tightly connected to the foundation.

4. Place the main machine on the base and adjust the level and verticality.

5. Connect the power and air source for electrical and air circuit debugging.

6. Machine debugging and calibration, including workbench height, tool installation and axial motion accuracy.

7. Install accessories and accessories, such as fixtures, tools, etc.

8. Conduct safety checks to ensure that protective devices are in good condition and operators are trained.

9. Start the machine for trial operation and debugging.

Follow the installation manual and relevant standards, and consult a professional if necessary.

About Company

Dezhou XinHongJi CNC Machinery Co., Ltd. Mainly engaged in Skiving Roller Burnishing,Hole Boring Machine,Honing Machine manufacturing.

We assure you that we will continue to serve our customers.

Engineering case

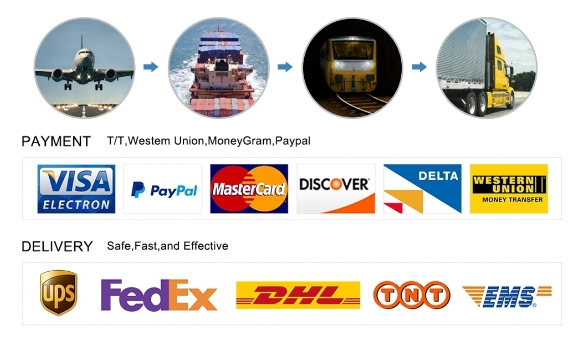

Payment and Transport